TPO (Thermoplastic Polyolefin) Single Ply Commercial Roofing Membranes have been manufactured by Koster for more than 25 years. During this time Koster have developed a product which is long lasting and guaranteed for up to 25 years, as well as being environmentally friendly and plasticiser free.

Koster TPO single ply roofing membrane is perfectly suited to quick and easy application. The product is resistant to UV rays and high mechanical stress: its crack bridging ability withstanding temperature induced movement.

The flexible TPO membrane is either mechanically fixed, fully bonded or loose laid with ballast and in each case the seams are hot air welded allowing safe application even in problematic areas. The thermoplastic characteristics of the Koster membrane create an inseparable, durable and homogeneous bond.

Koster have an Approved Installer Network of experienced roofers within the UK. Please contact us for further details.

As well as the TPO Single Ply Roofing Koster offer liquid applied roof waterproofing and a cold self adhesive sealing membrane.

1 Substructure

2 Vapor Barrier

KÖSTER Vapor Barrier LFL

3 Insulation

4 KÖSTER TPO Membrane

KÖSTER ECB 2.0

KÖSTER TPO 1.5

KÖSTER TPO 1.8

KÖSTER TPO 2.0

KÖSTER TPO Pro 1.2 W

The most common method of installing TPO membranes is through mechanical fastening. The membrane is mechanically fastened to the roof structure, which can consist of either wooden sheathing, trapezoidal sheets, or a concrete slab. The membrane is generally fastened through the thermal insulation, which requires special fasteners. Overlapping the membranes prevents the penetration of water into the installation.

Due to its great compatibility with various materials such as bitumen, the KÖSTER TPO Membrane is suitable for use in the renovation of roof waterproofing systems as well. For instance, the KÖSTER TPO Membrane can be directly fastened to the substructure without having to remove the old waterproofing system as long as the substrate is intact and structural aspects do not indicate otherwise.

Mechanical fastening allows for a quick installation and provides a high resistance to wind loads without placing an additional load upon the waterproofing system. Thus, the roof structure is comparatively light in weight. Furthermore, mechanical fastening guarantees that the membrane will not slip, even on pitched roofs.

Mechanical fastening even makes a green roof on a pitched roof possible.

1 Substructure

2 Insulation

3 KÖSTER TPO Membrane

KÖSTER TPO 2.0 F

Full surface adhesion to the substrate offers a time-saving installation.

The KÖSTER TPO Membrane features a special fleece coating which increases the bonding of the KÖSTER Polyurethane membrane adhesive. This results in a high adhesive strength and creates a perfect bond to the substrate.

It is important that the substrate is suitable for a good adhesive bond. If necessary, an adhesive bridge can be applied.

In addition, a wind load calculation must be carried out prior to the adhesion of the membrane in order to provide information about the amount of adhesive required and the alignment of the welding seams.

The KÖSTER Polyurethane membrane adhesive is applied in strips to the substrate, the fleececoated KÖSTER TPO Membrane is unrolled, and the membrane is firmly pressed onto the substrate using a rubber hand roller. This enables the adhesive to be spread evenly and help achieve uniformity of the bond.

When distributing the adhesive care must be taken to ensure that no material is applied to an area that is to be welded to another sheet.

1 Substructure

2 Vapor Barrier

KÖSTER Vapor Barrier LFL

3 Insulation

4 KÖSTER TPO Membrane

KÖSTER ECB 2.0

KÖSTER TPO 1.5

KÖSTER TPO 1.8

KÖSTER TPO 2.0

KÖSTER TPO Pro 1.2 W

5 Protection Layer

6 Ballast System

A quick and secure way to install KÖSTER TPO Membranes is through loose laying with ballast. Ballast can consist of either gravel, paving slabs, or even green roofs.

Ballast helps protect the roofing membrane against wind loads and can accommodate a wide range of architectural styles.

A special advantage of this installation method is that the roofing membrane does not need to be mechanically fastened to the substrate. Due to the weight of the ballast, higher loads must be taken into consideration in the roof load calculation.

1 Substructure

2 Insulation

3 KÖSTER TPO Membrane

KÖSTER TPO 1.5 SK (FR)

The self-adhering layer guarantees immediate, long-term adhesion and provides maximum protection against wind suction forces. The safe and easy welding of the overlaps with a hot air gun complete the installation advantages of the KÖSTER TPO SK (FR) single layer roofing system. Hardly any other material is as well suited for the waterproofing of roofs as thermoplastic polyolefin (TPO).

KÖSTER TPO SK (FR) Roofing Membranes are hail resistant, UV-stable, and have a high cold flexibility down to - 50 °C. Additionally, an embedded glass fleece provides the membrane with high stability. KÖSTER TPO SK (FR) Roofing Membranes are plasticizer-free and are compatible with all insulation types.

KÖSTER TPO SK (FR) Roofing Membranes are classified as Broof (t1) and meet the requirements for “hard roofs“ in accordance with DIN 4102-7. Moreover, KÖSTER TPO SK (FR) Roofing Membranes are suitable for installation directly over EPS insulation materials.

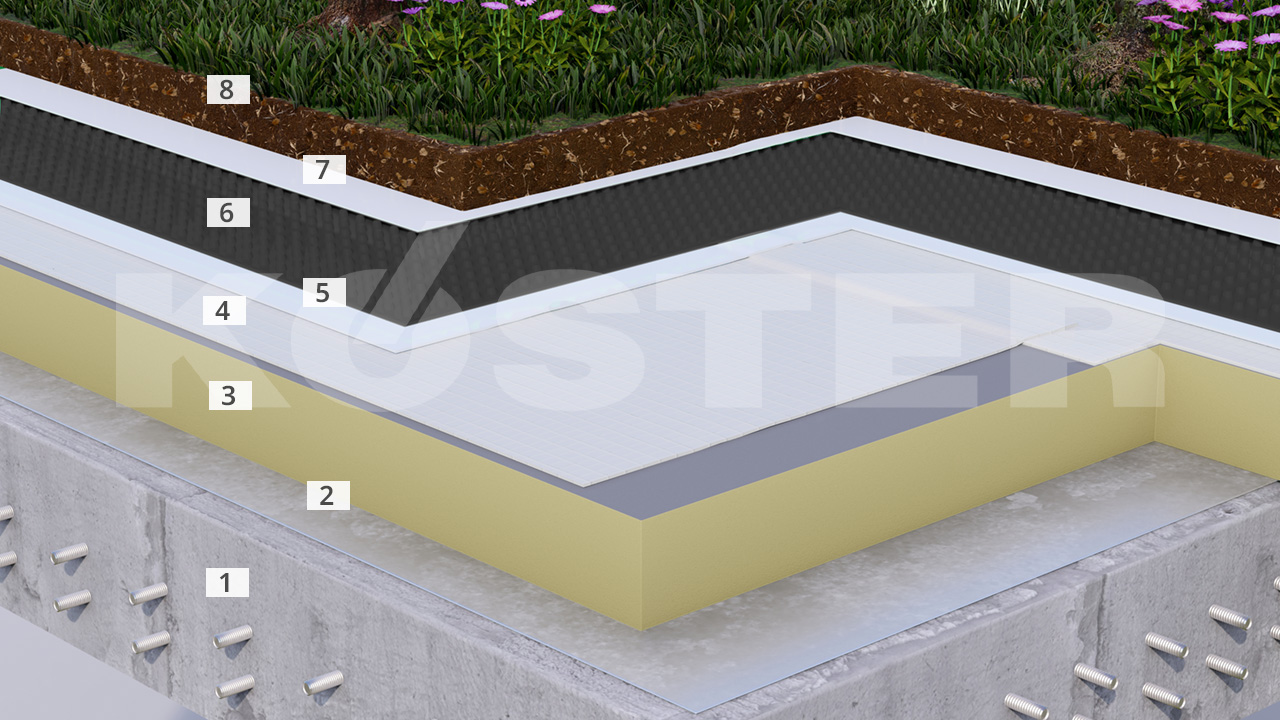

1 Substructure

2 Vapor Barrier

KÖSTER Vapor Barrier LFL

3 Insulation

4 KÖSTER TPO Membrane

KÖSTER TPO 1.8

KÖSTER TPO 2.0

5 Protection Layer

7 Protection Layer

8 Ground / Greenery / Landscaping

Roof waterproofing with loose-laid membranes on green roofs

1 Primer

KÖSTER KBE Liquid Film

Smaller roofs on non residential buildings can quickly and easily be waterproofed with the cold self-adhesive sealing membrane KÖSTER KSK Alu Strong. The clean and dry substrate is primed with KÖSTER KBE Liquid Film. In case of temperatures below 0°C KÖSTER KSK Primer SP is used as a primer. KÖSTER KSK Alu is applied onto the dry and primed roof area. Membranes have to overlap a min. 10 cm on each side. Connections, penetrations and overlaps are sealed with KÖSTER KBE Liquid Film.

Always adhere to the specifications in the respective Technical Guidelines.